|

|

THIS SPACE IS FOR FINISH AMPLIFIER PICTURE |

|

|

|

Boring Stuff:

Here's another amplifier project of

mine. And still learning lots of thing as I build. I suddenly

got the Six Meter bug so why not build a 6 meter amplifier. I

did lots of research on Six meter amps and look at all the

different designs and schematic I could fine. And with that I

will try an incorporate some of these into my own project.

If your thinking of building your first

amp. Be prepare to do a lot of metal work, and this is were

you'll be spending a lot of time. And be sure to plan out your

project as much a possible. It will help I

you throw out your project.

The first thing I've learn when starting

a amplifier project is to decide on what tube or tubes your

going to use. And then start with your power supply section.

The transformer for this project came from a old beat up

Heathkit SB-200 amp I've had for 20 some years. Also made use

of other parts from this amp.

Tube's for this project is a pair of

Russian GI7B tubes. Ok so Let me get started. One thing you

need to do before using these tubes is to burn in the filament

for at lease 48 hours before applying

any High voltage to them.

|

|

|

Power

Supply:

The first

part of this project is to build the power supply

section and get it all working correctly. The

transformer is from my beat up old Heathkit SB-200

amplifier. The capacitor and rectifier board is also

from the Heathkit SB-200 amp along with the breaker.

Since I decide not to re-build it, I decided to make use

of the parts.

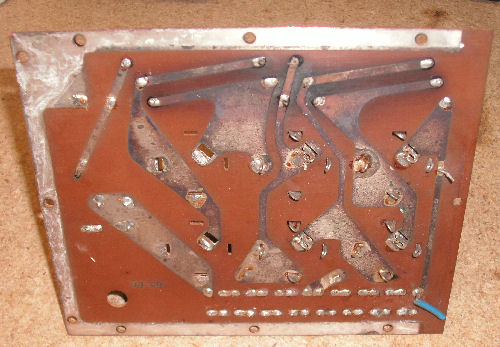

The

transformer was check out and still working. I then

clean it up and repainted it. The

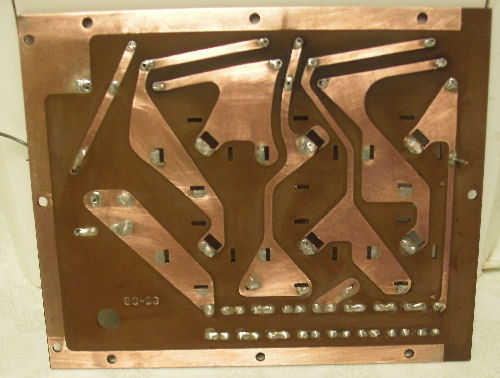

filter capacitor and rectifier PCB is being re-used. I

remove all the components and clean up the board.

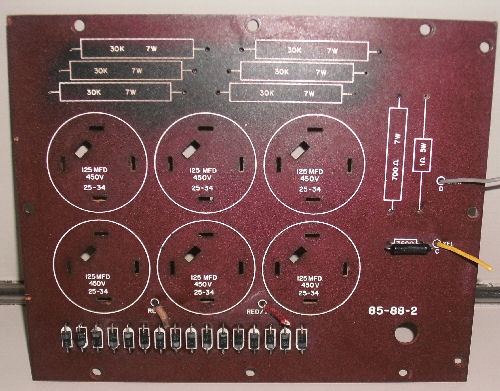

Image 1 shows the PCB before removing all of the

components and before cleaning. Image #4 shows the

bottom of the board before cleaning and image #5 shows

after. The same goes for the top of the PCB.

As you can see from the images 6 and 7 there's

nothing I can do about the burn or heat marks left on

the board which was cause by heat from the 30K 7 watt

bleeder resistors.

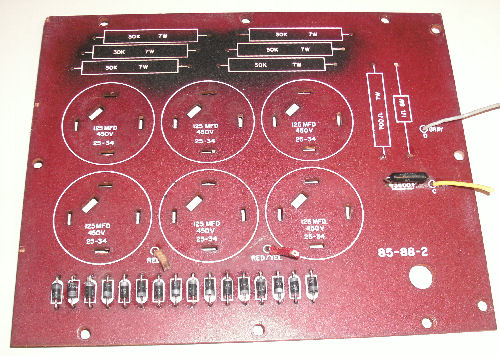

I replace the 30K 7 watts bleeder's with 30K 10 watts

resistor because this it what I had on hand. I

should have replace them with another type of resistor

what would product much least heat and a lower

wattage. Since the power supply section of the

amplifier will not be enclose and will

be rack mounted the heat will not be trap inside the

case. Hopefully this will help to keep things cooler.

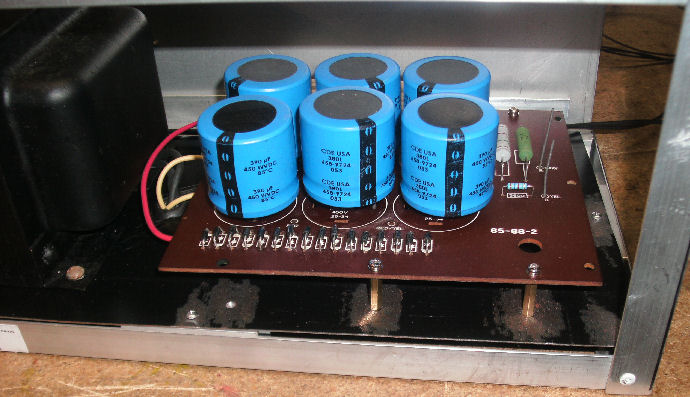

The original 16 rectifier diodes were replace with

1N4007 diodes. The capacitor bank are 390uf 450 volts.

The reason I choose this value was to stiff up the

voltage and in turn to keep from having a big voltage drop under

full load.

Pictures 8 and 9 show how the newer capacitors were

fitting to the old PCB. I used the ends from some very

old resistor I have. Cutting the ends of the resistors

and then wrapping them around each leg of the new

capacitors and then soldering them to the old sb-200

PCB. This was not my idea I have seen this on another

site some where.

Testing The Board:

Next step was testing out the PCB board. Looking at pictures 10 and 11 you can

see with 124.8 volts ac input the supply is delivering

2,335 VDC

out. My line voltage vary from 122vac to 125vac.

New Components:

Pictures 12, 13,14,15 shows the capacitor board with

all new components added.

This is just a re-built SB-200 power supply with bigger

components. The schematic is the same other then some

small changes.

Clicking on a image will

give a larger view. You may have to scroll down the

screen a bit to view. Still trying to figure out how

to fix this. |

|

Heathkit SB-200 Transformer

|

SB-200 PCB (1)

|

SB-200 PCB (2)

|

SB-200 PCB (3)

|

Bottom Before Cleaning (4)

|

| |

After Cleaning (5)

|

Top After Cleaning (6)

|

Top After Cleaning (7)

|

(8)

|

(9)

|

| |

HV Test (10)

|

HV Test (11)

|

New Parts (12)

|

New Parts (13)

|

New Parts (14)

|

| |

|

|

|

|

|

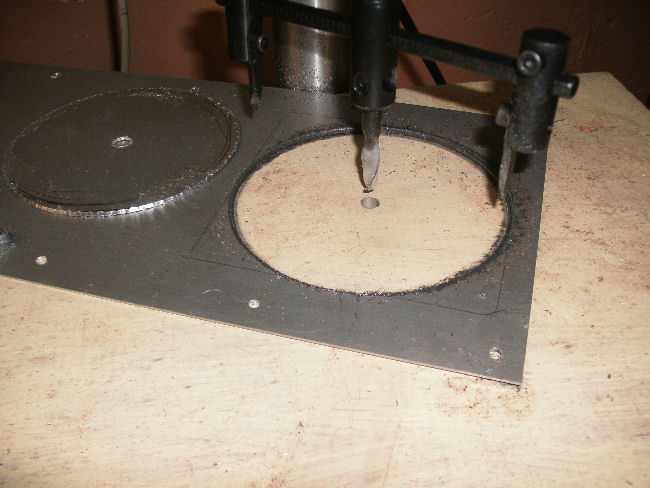

Chassis

Construction:

I won't going into

a lot of detail on how to build a chassis as this

is all up to the builder. I will show some details

was to what I did. I must say this. You will

need to

put a lot of though into your construction. And

where your going to mount your parts ahead of time. And try to drill out

most of your holes before

placing them into the chassis if possible. I used

aluminum angle for my frame work. Also found

a large piece of steel sheeting that I think came

out of some type of

locker of file cabinet laying around at work. This

was used to make the bottom panel in the chassis. I had to

cut the bottom sheet into two piece because after putting the frame

work together, I

could not place the hole bottom panel in place. The

frame work was all riveted together. The

aluminum angle was purchase from Home Depot. The

aluminum used to make the

rack mount front panel was purchase from Metal By The

Inch. You can do a internet search to fine them.

And there price's

I fine to be must better other online metal companies.

So far I have found a few miss stack in my own

construction but I can work around them LOL. Still

learning. |

|

Frame Work (1)

|

Frame Work (2)

|

Frame (3)

|

Bottom Plate In Frame (4)

|

Capacitor Placement (5)

|

|

Cutting Hole for Fan (6)

|

Meter & Switch Hole Cut (7)

|

|

| |

|

| |

|

|

|

|

|

Miscellaneous Stuff:

Plate Voltage & Plate Current

Metering:

I put together a voltage dropping resistor for

the HV metering circuit which consist of (4) 750k ohm 3 watt

resistor for a total of 3 meg ohm. The resistor are

connected in series. This is so the

meter will read up to 3kv DC. Fig 1 show the dropping

resistors on perforated board with stand off soon to

be mounted. Fig 2 shows meter with the original scale.

Fig 3

Plate voltage and plate current meter with new scale.

Fig 4 Grid current meter with new face plate.

All meters are

0-1ma purchase from All Electronic Corp.

Fig 5 Plate Choke: The plate choke is home brew, wound

with number 22ga enamel wire about 55 turns on a

Fig 6 Filament Choke: Filament choke is also homebrew

on a 7 1/2" ferrite rod. You don't need this long of a rod

it's what I had on hand. Has you can see from the picture

I'm not using the

complete rod. The rod is wound using #14ga house wire some

40 turns using tie wraps to hole the ends together.

|

|

Meter Dropping Resistors (1)

|

Meter Dropping Resistors (2)

|

Picture To Be

Added

Meter With New Scale |

Picture To Be

Added

Meter With New Scale |

Plate Choke (5)

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |